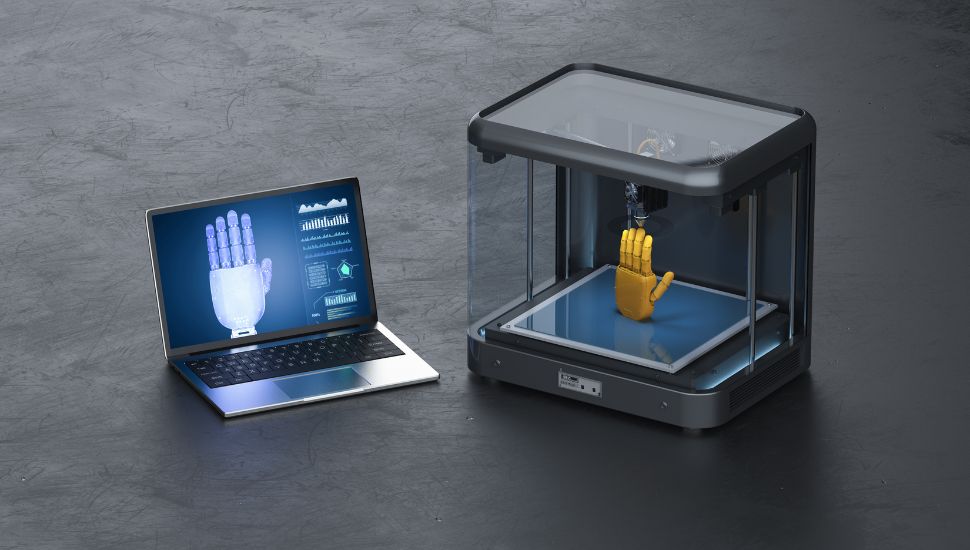

In today’s digital age, technology is constantly evolving and pushing the boundaries of what is possible. One area that has seen significant advancements is the field of 3D printing.

This innovative technology has revolutionized various industries, from healthcare to manufacturing. Now, it is making its way into the world of photography with the possibility of 3D printed cameras.

This article will explore the potential of 3D printed cameras and how they could change the photography industry.

Introduction to 3D Printing Technology

Before diving into the world of 3D printed cameras, it is important to understand what 3D printing technology is and how it works.

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials on top of each other.

It starts with a digital design file that is sliced into thin layers, which are then printed layer by layer until the final object is created.

There are several types of 3D printing technologies available, including fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and digital light processing (DLP).

Each technology has its own advantages and limitations, but they all share the same basic principle of building objects layer by layer.

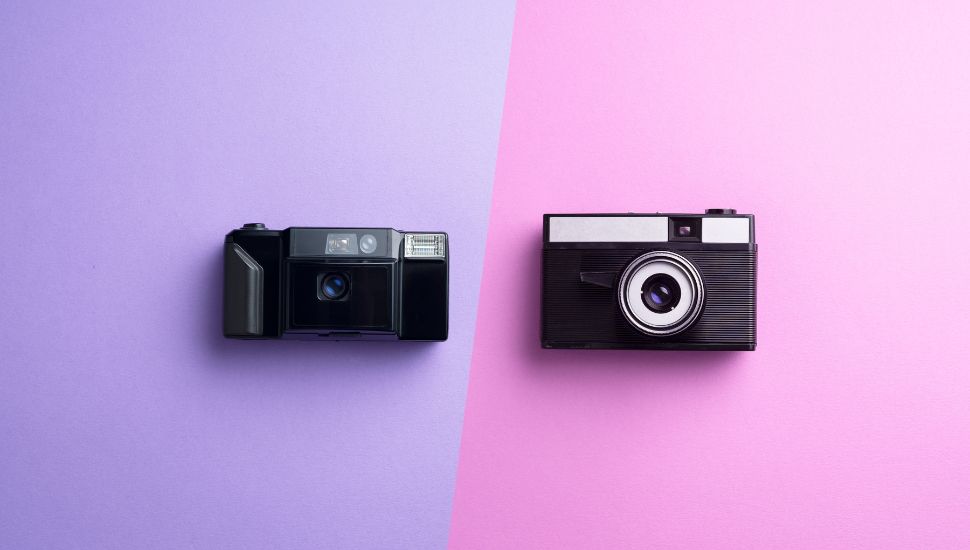

The Evolution of Camera Technology

Cameras have come a long way since their inception in the early 19th century. The first camera, known as the camera obscura, was a simple device that projected an image onto a surface.

Over time, cameras evolved to include film, which allowed for the capture and storage of images.

With the advent of digital technology, cameras underwent a major transformation. Digital cameras replaced film with electronic sensors that captured light and converted it into digital data. This allowed for instant image preview and storage on memory cards.

Today, we have smartphones with built-in cameras that are capable of capturing high-quality images and videos. The evolution of camera technology has made photography more accessible and convenient for everyone.

The Benefits of 3D Printed Cameras

The idea of 3D printed cameras may seem like a novelty, but there are several benefits to exploring this possibility.

One of the main advantages is customization and personalization. With 3D printing, cameras can be designed and manufactured to meet the specific needs and preferences of individual photographers.

This means that photographers can have cameras that are tailored to their unique shooting styles and requirements.

Another benefit of 3D printed cameras is cost-effectiveness. Traditional camera manufacturing involves complex processes and expensive tooling, which can drive up the cost of production.

With 3D printing, the need for tooling is eliminated, resulting in lower production costs. This cost savings can be passed on to consumers, making cameras more affordable and accessible.

Additionally, 3D printing allows for faster production time. Traditional camera manufacturing can take weeks or even months to complete, as it involves multiple steps and processes.

With 3D printing, cameras can be produced in a matter of hours or days, depending on the complexity of the design.

This means that photographers can get their hands on new cameras more quickly, without having to wait for extended periods of time.

Furthermore, 3D printing reduces waste in the manufacturing process. Traditional manufacturing often results in excess materials and parts that are discarded.

With 3D printing, only the necessary amount of material is used to create the object, minimizing waste. This is not only more environmentally friendly but also more cost-effective.

The Role of 3D Printing in Camera Manufacturing

3D printing is already being used in various industries, including aerospace, automotive, and healthcare. In the field of camera manufacturing, 3D printing has the potential to revolutionize the way cameras are made.

Currently, 3D printing is primarily used in the prototyping stage of camera development. It allows manufacturers to quickly create physical models of new camera designs, test them, and make necessary modifications before moving on to mass production.

This speeds up the product development cycle and reduces the time and cost associated with traditional prototyping methods.

In addition to prototyping, 3D printing can also be used to produce certain camera components.

For example, lens hoods, tripod mounts, and other accessories can be 3D printed, providing photographers with a wider range of options and customization possibilities.

The Future of 3D Printed Cameras

The future of 3D printed cameras holds great potential for advancements in technology and design. As 3D printing technology continues to improve, we can expect to see more complex and sophisticated cameras being produced.

One potential advancement is the integration of multiple materials in 3D printed cameras. Currently, most 3D printers can only print with a single material at a time.

However, researchers are working on developing multi-material 3D printers that can print with different materials simultaneously.

This would allow for the creation of cameras with components made from different materials, each optimized for its specific function.

Another potential advancement is the use of 3D printing to create lenses. Lenses are one of the most critical components of a camera, and their design and manufacturing require high precision.

With advancements in 3D printing technology, it may be possible to 3D print lenses with complex shapes and optical properties, resulting in improved image quality.

Customization and Personalization of 3D Printed Cameras

One of the key advantages of 3D printed cameras is the ability to customize and personalize them. With traditional cameras, photographers are limited to the designs and features offered by manufacturers.

However, with 3D printing, photographers can have cameras that are tailored to their specific needs and preferences.

For example, photographers can customize the ergonomics of the camera body to fit their hand size and shooting style. They can also add or remove features based on their requirements.

This level of customization allows photographers to have cameras that are truly unique and optimized for their individual needs.

There are already examples of customized 3D printed cameras in the market. For instance, the OpenReflex camera is an open-source 3D printed camera that allows users to customize and modify various components.

This camera has gained popularity among photography enthusiasts who enjoy tinkering and experimenting with different designs.

The Impact of 3D Printed Cameras on Photography

The introduction of 3D printed cameras could have a significant impact on the way we take photos.

With the ability to customize and personalize cameras, photographers can have tools that are specifically designed for their shooting style and preferences. This could result in improved image quality and more creative possibilities.

Additionally, 3D printed cameras could introduce new features and capabilities that are not currently available in traditional cameras.

For example, cameras could be designed with built-in accessories such as lighting attachments or filters. This would eliminate the need for external accessories and make the camera more versatile and convenient to use.

Furthermore, 3D printed cameras could enable photographers to experiment with unconventional designs and form factors.

Traditional cameras are often limited by their size and shape, but with 3D printing, cameras can be created in any shape or size imaginable. This opens up new possibilities for unique and innovative camera designs.

The Challenges of 3D Printed Camera Production

While the potential of 3D printed cameras is exciting, there are several challenges that need to be addressed in order to produce high-quality cameras using this technology.

One of the main challenges is the limitation of current 3D printing technology. While 3D printers have come a long way, they still have limitations in terms of resolution, accuracy, and material properties.

Producing cameras with high precision and optical quality requires advanced 3D printing technology that is not yet widely available.

Another challenge is the production of complex camera components. Cameras consist of various intricate parts, such as gears, springs, and shutters, which are difficult to 3D print accurately.

These components often require high precision and specific material properties that are challenging to achieve with current 3D printing technology.

Furthermore, the durability and reliability of 3D printed cameras need to be addressed. Traditional cameras are built to withstand the rigors of daily use and last for many years.

Ensuring that 3D printed cameras can meet these standards will be crucial for their acceptance in the market.

The Cost-Effectiveness of 3D Printed Cameras

One of the key advantages of 3D printed cameras is their potential cost-effectiveness. Traditional camera manufacturing involves complex processes and expensive tooling, which can drive up the cost of production.

With 3D printing, the need for tooling is eliminated, resulting in lower production costs. Additionally, 3D printing allows for on-demand production, which means that cameras can be produced as needed, reducing inventory costs.

This is particularly beneficial for small-scale manufacturers or individual photographers who may not have the resources to produce cameras in large quantities.

Moreover, 3D printing enables the use of less expensive materials without compromising on quality. Traditional camera manufacturing often requires specialized materials that are more expensive.

With 3D printing, a wider range of materials can be used, including lower-cost options, making cameras more affordable for consumers.

Best 3D Printed Cameras in 2023

1: Raspberry Pi Camera Module V3

The Raspberry Pi Camera Module V3 is a camera accessory created specifically for use with Raspberry Pi computers. It is available with two lens options: a 75-degree standard lens or 120-degree wide-angle lens.

The camera module has a compact size measuring approximately 25 x 24 x 11.5 mm or 25 x 24 x 12.4 mm depending on the lens type. Both regular and infrared/night-vision versions can be purchased.

This latest version provides improved specifications such as 1080p video resolution at 50 frames per second, which is an upgrade from the 30 fps capability of earlier models.

Additional new features include autofocus replacement of manual focus and high dynamic range (HDR) mode. These enhancements allow for better quality documentation of 3D printing projects.

As the camera requires assembly, users have developed various 3D printed mounting designs that either house or attach the module for time-lapse monitoring of printers.

#2: Raspberry Pi High Quality Camera

Intended for high resolution time-lapse videos, the Raspberry Pi High Quality Camera features a 12.3 MP Sony image sensor providing better imaging than comparable cameras.

It supports changeable wide-angle and telephoto lens options sold separately. Lenses connect using M12 or CS mounts, permitting use of third party 16mm alternatives as well.

While offering advanced specifications, the modular construction necessitates technical proficiency to set up and adjust focus.

However, an integrated tripod mount simplifies positioning. This camera is best suited to experienced Raspberry Pi users.

#3: Logitech C270

The low-cost Logitech C270 remains a popular choice for 3D printing camera use due to its affordable price point and 720p video capability.

Although featuring autofocus, some users employ manual focus techniques. It includes a mounting base but 3D printed versions provide increased flexibility of placement.

A large number of customization designs can be found on websites like Thingiverse, inspired by the camera’s widespread adoption.

3D printed mounts allow for customized installation matching various printer setups and desired viewing angles.

#4: Amcrest AWC195-B

The Amcrest AWC195-B camera provides high value for its image quality and versatile mounting options.

While the 1080p resolution at 30 frames per second is not the highest specification, it should perform well enough for monitoring 3D printer progress. The setup is straightforward and the affordable price point makes it a practical choice.

This camera includes both a built-in privacy cover and removable stand for mounting flexibility. The stand can attach directly to the camera or a tripod for positioning around a printer workspace.

An approximately 175 cm long USB 2.0 cable allows convenient placement without constraint. Based on user reviews, the AWC195-B captures usable footage even in low light conditions.

While lacking advanced features, it functions reliably as an basic monitoring solution suitable for most hobbyist needs. The combination of functional design, easy setup

Conclusion:

In conclusion, the potential of 3D printed cameras in the photography industry is vast. With the ability to customize and personalize cameras, photographers can have tools that are tailored to their specific needs and preferences. This could result in improved image quality and more creative possibilities.

Furthermore, 3D printed cameras could introduce new features and capabilities that are not currently available in traditional cameras.

The ability to experiment with unconventional designs and form factors opens up new possibilities for unique and innovative camera designs.

While there are challenges to overcome, such as the limitations of current 3D printing technology and the production of complex camera components, the future of 3D printed cameras looks promising.

As technology continues to advance, we can expect to see more sophisticated and high-quality 3D printed cameras in the market.